FTE is Paying Forward Durability, Reliability and Fuel Efficiency to Customers

In 1976, Grant Smyth and Gunte Janke’s one year old business, Fiberglass Transport Equipment (FTE), built their first temperature-controlled unit for Castlemaine Bacon who wanted a cash sales van to sell bacon and smallgoods direct to public.

Over 40 years later, and building close to 300 units per year, Victoria-based FTE has become known as the market leader in the Australian temperature-controlled road transport equipment environment, manufacturing and supplying lead trailers, semi-trailers and rigid vans for the food industry, mainly.

Carting fresh produce, groceries and meat products, as well as pharmaceuticals and other temperature sensitive products, FTE’s customers from all over Australia rely on what makes the company the most sought after in the industry: superior thermal efficiency with their unique bonded construction of bodies that provides fewer thermal bridges.

Fully bonded or moulded, the bodies of FTE’s temperature-controlled units are free of any mechanical type fasteners, which means no thermal ‘leakage’ from drilling of holes to hold panels together.

For food product companies who need to travel in temperatures in the high 30s and often 40s, it is imperative that the produce is kept at a steady temperature without risk of this thermal leakage compromising the refrigeration.

The unique bonded construction of all FTE equipment also results in outstanding fuel efficiency and a K value that surpasses the Australian Standard.

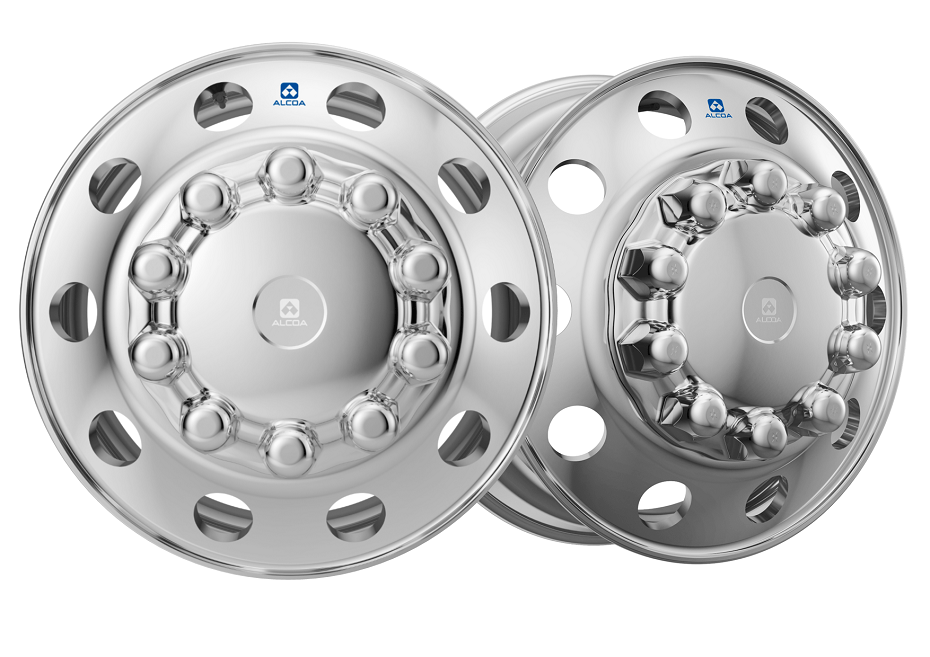

IMAGE: This Ron Finemore Transport PBS 26 Pallet trailer on Alcoa Wheels was added to their upwards of 500 trailing equipment pieces used for their regional and inter-capital city line-haul of food, produce, manufactured goods and bulk liquids.

What makes a company like FTE retain their market leader status is their commitment to the highest quality, which means continuously assessing the body strength, durability and design of equipment across all parts of production, including the wheels.

One thing that hasn’t changed for a couple of decades, is FTE’s preferred wheel of choice: The Alcoa® Wheel.

A match to their exceptional equipment standards with not only its strength, durability, and fuel efficiency, Alcoa wheels are but backed by over 75 years of innovation and commitment to equally high standards.

This pride in their customer service and in the upkeep of their modern fleet of over 120 prime movers and wide range of trailing equipment is evident in their choice to rely on Alcoa wheels for 15+ years, and to now standard spec Alcoa Dura-Bright® wheels.

According to Andrew, they present well, they suit the tough, remote environments Corbet’s equipment work in and they add value to their fleet.

“Alcoa have been a staple to the transport industry and our business,” says Jason Cunningham, National Sales Manager for FTE. “The reliability and consistency we get from their product range helps provide the best possible equipment for our customers.”

IMAGE: Martin Brower commissions temperature-controlled equipment on Alcoa wheels from FTE for their deliveries into McDonalds stores.

With fuel efficiency being one of the hottest topics right now, and FTE’s equipment built to run efficiently, Alcoa wheels are an integral addition to the mix as they are relied on by companies like FTE to help their customers save more fuel, improve tyre performance, carry more load, and reduce maintenance costs.

The Alcoa wheels and FTE partnership goes back well over 25 years, with FTE becoming one of Alcoa’s earliest customers when aluminium wheels were first introduced to Australia.

Customers of FTE today specify a combination of polished Alcoa wheels and Dura-Bright® wheels, according to their preference:

- The Alcoa Ultra ONE® 22.5” x 8.25” wheel is the lightest and strongest in the market, weighing in at just 18kg, compared with an average 23kg of other standard aluminium wheels, while being able to carry the same load, which means the equipment produces better fuel efficiency and more payload.

- Alcoa Dura-Bright® wheels wheels take lowering maintenance to another level with their patented surface treatment that actually penetrates the surface of the aluminium and forms one composite to prevent filiform corrosion and ultimately, won’t peel or crack, which is often seen in coated wheels.

For fleets that uphold an impeccable image, like many who commission FTE to build their temperature-controlled equipment, Dura-Bright® wheels make it easier by saving labour and time with their consistent shine without the need to polish.

Available across the Alcoa Wheel range, including the 18kg Ultra ONE® wheel, Dura-Bright® wheels combine strength, light weight and low maintenance for an all-round solution to support the bottom line.

“FTE and Alcoa Wheels have been a good match for decades, and our commitment to innovating to give our customers the best products in the market continue to align,” says Ross Simmons, Managing Director of Howmet Wheel Systems, distributor of Alcoa Wheels in Australia.

What’s FTE bringing into the market right now? As PBS vehicles are the hot topic, FTE is using its expertise in the temperature-controlled equipment space to trial different combinations and axle configurations to further meet their customers’ requirements.

IMAGE: 26 Pallet PBS unit custom-built for Jim Pearson Transport by FTE for their line-haul of large freight volumes of refrigerated goods between Sydney and Brisbane.

Make Sure It’s An Alcoa® Wheel When You Buy Your Next Truck or Trailer

To spec your wheels for your equipment, ring 1800 955 191 to talk with our wheel experts, or fill out a contact form and we will reach out to you to answer your questions and discuss your specifications.