Maintenance is a critical component to ensure the safety of fleets and their drivers, along with owner-operators and even other drivers and vehicles on the road.

Wheel maintenance is a significant contributor to the overall efficiency, lifetime operating costs and appearance of commercial vehicle wheels, particularly when it comes to monitoring for rim flange wear.

“Excessive rim flange wear is one of fleets’ primary safety and maintenance concerns,” says Ross Simmons, Managing Director of Howmet Wheel Systems, distributor of Alcoa Wheels in Australia. “It’s one of the most common maintenance conditions experienced by a number of heavy hauling fleets across Australia and the costs can be managed if they can avoid excessive rim flange wear by catching it early.”

While this can be a concern for fleet managers who are tasked with keeping maintenance costs down and preventing wheel offs and too much down time, the good news is that rim flange damage is less harmful to the wheel than to the tyre. Sharp edges in the flange can damage the tyre bead and, while it’s more common with aluminium wheels, it can be repaired if detected in time.

What is Rim Flange Wear?

Rim flange wear is the irregular wear on the surface of the rim flange of commercial vehicle wheels. It looks like abrasive wear and/or pitting and is found at the top of the rim flange.

Rim flange wear can become quite severe and sharp and it can damage tyres when a tyre is being demounted from a wheel that had a severe case of wear with sharp edges on the rim flange.

What causes Rim Flange Wear?

In a nutshell, it’s abrasion that causes rim flange wear.

Rim flange wear happens when the weight of the loads being carried causes the sidewalls of the tyres to rub back and forth against the wheel flange, creating wear.

It can also be caused by using a wheel that is too narrow for the tyre and can also be worsened by corrosive or abrasive environments and applications, like tanker operations or in refuse applications, where the load shifts frequently.

It can occur especially when tyres are underinflated and/or overloaded.

After a while, the abrasion erodes the flange surface and causes sharp edges that damage the tyres, making replacement inevitable.

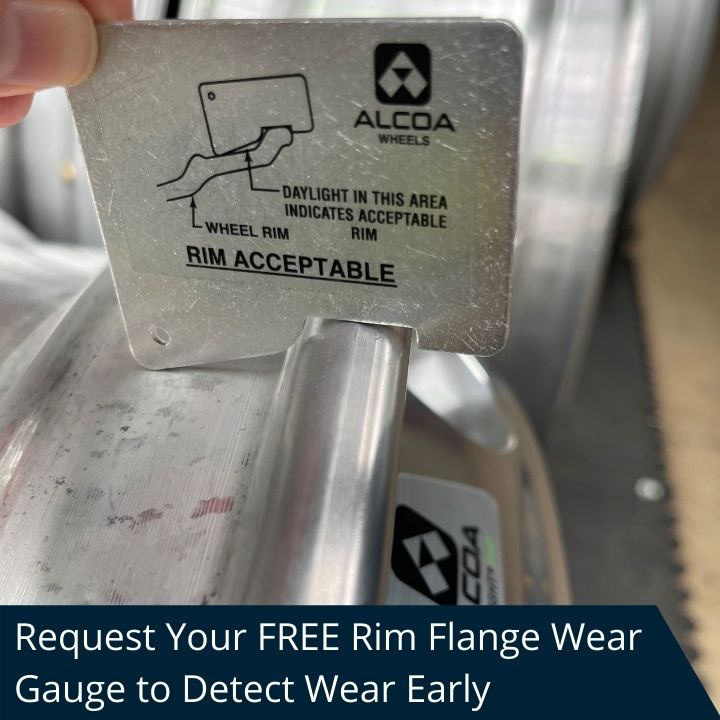

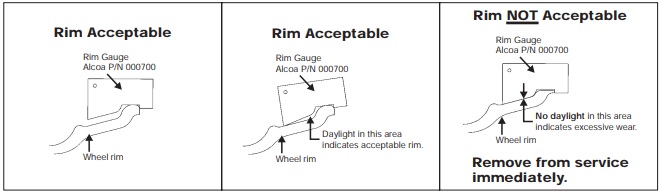

Alcoa Wheels supplies FREE Rim Flange Wear Gauges to help fleets and owner-operators keep an eye on rim flange wear, as well as a helpful manual for maintaining the rim flange on Alcoa Wheels.

Order your FREE Rim Flange Wear Gauge

The flange of the wheel is the critical design element that helps to keep the tyre airtight against the wheel and prevents the tyre from falling off. It’s crucial to maintain this surface during regular tyre changes for maximum safety and to reduce costs.

Alcoa Wheels has step by step instructions on ow to check rim flange wear which you can download below.

Enter your details HERE and we’ll pop a free Rim Flange Wear Gauge in the post to you.

Download the Alcoa Wheels Rim Flange Maintenance Guide for Step-by-Step instructions on how to reduce and maintain Alcoa Wheels rim flange wear.

(If you would like a Rim Flange Wear Gauge mentioned in the guide, click HERE and we’ll send you one in the post along with a hard copy of the Guide.)

Going Forward

As the industry moves toward more and more aluminium wheels being used because of their lighter weight advantages for fuel-efficiency and lowered CO2 emissions, staying on top of rim flange wear maintenance will need to be close to the top of the list for fleets and owner-operators.

Make Sure It’s An Alcoa® Wheel

To spec your wheels, ring ![]() 1800 955 191 to talk with our wheel experts, or fill out a contact form and we will reach out to you to answer your questions and discuss your specifications.

1800 955 191 to talk with our wheel experts, or fill out a contact form and we will reach out to you to answer your questions and discuss your specifications.