Our experts recently conducted an impact test where we put the strength of a forged aluminum wheel to the test versus a fabricated steel wheel. This test, known as the impact test, simulates a wheel and tire assembly hitting a curb while the vehicle is in motion. In the past, we included cast aluminum wheels in this study, and they proved to not fare well.

To best comprehend the results of the impact test, it is important to understand how wheels are made, and know their characteristics and properties. Therefore, refer to our most recent Expert Insights blog post on the different types of wheels and how they are made.

The characteristics and properties of cast, fabricated steel wheels and forged aluminum wheels:

1. Mechanical properties. Forged aluminum wheels have higher mechanical properties when compared to cast aluminum wheels. The weight of a cast aluminum wheel is higher than a forged aluminum wheel. When comparing a forged aluminum wheel to a fabricated steel wheel, the specific strength ratio to the weight of the wheel is significantly better for a forged aluminum wheel than for a fabricated steel wheel. The impact test conducted included two wheels designed for the same application—a 7,400 lb. load rating wheel. In one case, the forged aluminum wheels weighed 39 lbs and the fabricated steel wheels weighed closer to 70 lbs. That is a significant weight difference, which can have an impact on fuel mileage, as well as the carrying capacity of the truck being driven.

2. Impact properties. Impact properties for forged aluminum wheels are typically less because they maintain lower elongations and there are lower strengths associated with the cast aluminum wheels.

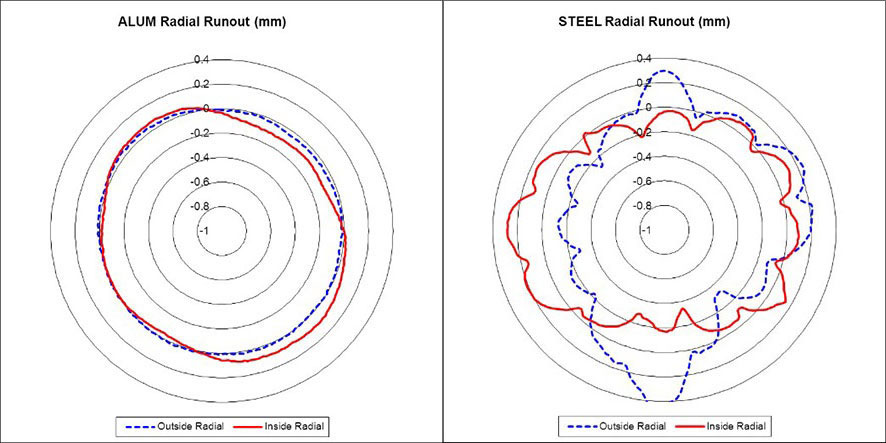

3. Uniformity. Uniformity affects tire life, which can result in a lateral and radial runout situation. For those who have driven a vehicle and watched the wheel go down the road, looking wobbly, that is considered a lateral runout. Radial runouts can also occur, which appear when tires go up and down. There is also a situation where we have a radial runout, and you may have seen tires that go up and down. create an unexpected wear on the tires that impacts the overall tire life

Out of round measured versus steel wheel

Learn more about radial and lateral runout on the ”A Balancing Act” episode of the Behind the Wheels podcast.

4. Thermo Conductivity. Aluminum is three times more conductive than steel. Forged aluminum wheels dissipate heat better, which means they offer true, cool running contributing to longer life for tires, brakes and suspensions. This becomes important when considering tire life. A study completed in Phoenix, AZ compared a forged aluminum wheel to a fabricated steel wheel. The study showcased a waste truck application and found that, during the day, the fabricated steel wheel ended up having a much higher elevated temperature than the forged aluminum wheel. And even at the end of the day when the trucks were parked, the temperature was retained for much longer in the fabricated steel wheel vs. the forged aluminum wheel.

5. Maintenance. Fabricated steel wheels are painted to protect them from the environment and the corrosion that occurs. Red rust on steel wheels is visible even as you drive down the road. Painted wheels require more maintenance as they need to be refurbished more frequently than a forged aluminum wheel. Aluminum is a metal that is highly resistant to corrosion, therefore it does not require sand blasting and painting. Many forged aluminum wheels on the market are highly polished, which consumers prefer, because they last longer. If there is a need to return the luster to aluminum wheels, a simple polish can bring back the bright character of the aluminum.