When you’re in the market for a semi trailer, it’s easy to focus on the big-ticket items: the suspension, the body, the chassis. But what about the trailer wheels? Too often, they get pushed to the bottom of the checklist.

Here’s the thing—your choice of wheels doesn’t just influence how your trailer looks. It has a direct impact on performance, safety, operating costs, and ultimately, your business’s profitability.

Supporting the Load: The Real Business Benefit

Trailer wheels do more than roll. They carry the entire load of your trailer, including your payload. That makes them one of the most important profit drivers in your operation.

- More Payload, More Profit

Alcoa® Wheels are up to half the weight of steel wheels. Less wheel weight means you can carry more freight without breaching weight limits. Every extra kilogram of payload adds up to extra dollars in your pocket. - Reduce Tyre Wear

Lightweight aluminium wheels help distribute weight more evenly and run cooler, which means your tyres last longer. Considering tyres are one of the biggest ongoing costs for fleets, this can save thousands over time. - Lower Maintenance, Less Downtime

With less strain on tyres, suspension, and brakes, your trailer stays on the road longer. Less downtime means more time earning and fewer maintenance headaches.

In short: the right wheels don’t just support your trailer—they support your bottom line

The Direct Impact on Performance

Trailer wheels aren’t just passengers. They actively shape how your trailer behaves on the road. From precise turns to smooth acceleration and safe braking, they’re working quietly behind the scenes every kilometre.

Choosing premium trailer parts like Alcoa® means investing in a smoother, safer, and more reliable driving experience. And that translates into real savings in both time and money.

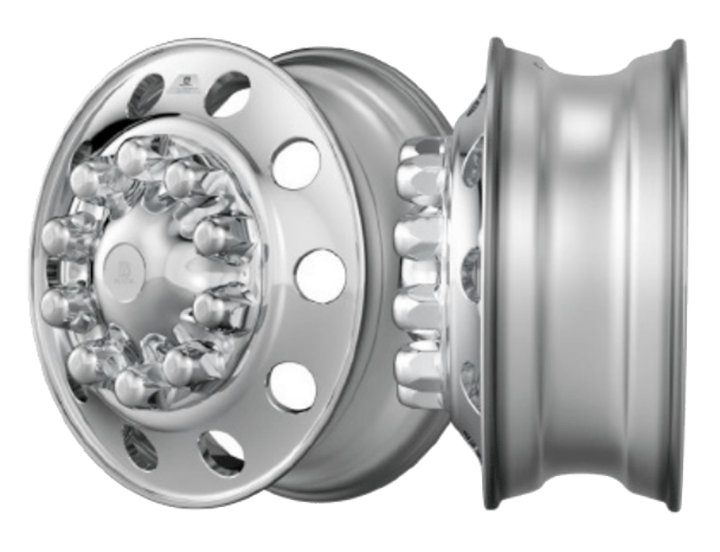

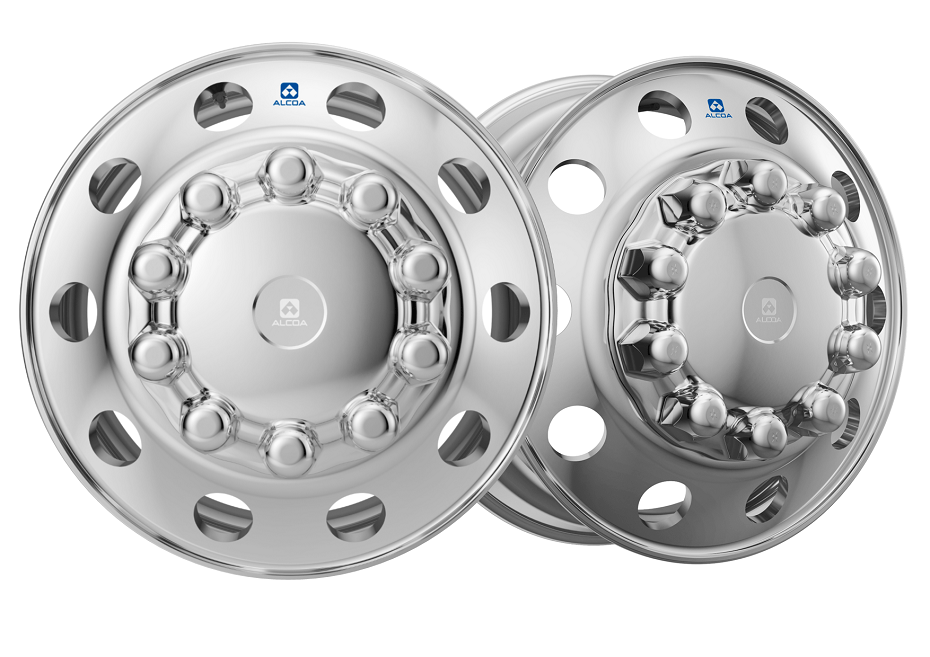

Appearance That Reflects Your Business

Of course, wheels aren’t all about function. They also make a statement. A polished set of Alcoa® Wheels signals professionalism, quality, and pride in your fleet. It’s a simple way to elevate your brand image while gaining all the performance benefits.

Why Choose Alcoa® Wheels?

Because they tick every box:

- Greater payload capacity

- Longer tyre life

- Reduced downtime

- Strong, reliable performance

- A polished, professional image

When you’re buying a semi trailer from Maxitrans, Vawdrey, etc, don’t let wheels be an afterthought. They’re not just accessories—they’re business assets. And when it comes to maximising payload, reducing costs, and projecting quality, there’s no better choice than Alcoa® Wheels.

Ready to Take the Next Step?

Contact our team today to learn more about how Alcoa® Wheels can improve your trailer’s performance and boost your bottom line. We’re here to help you find the perfect fit for your fleet.

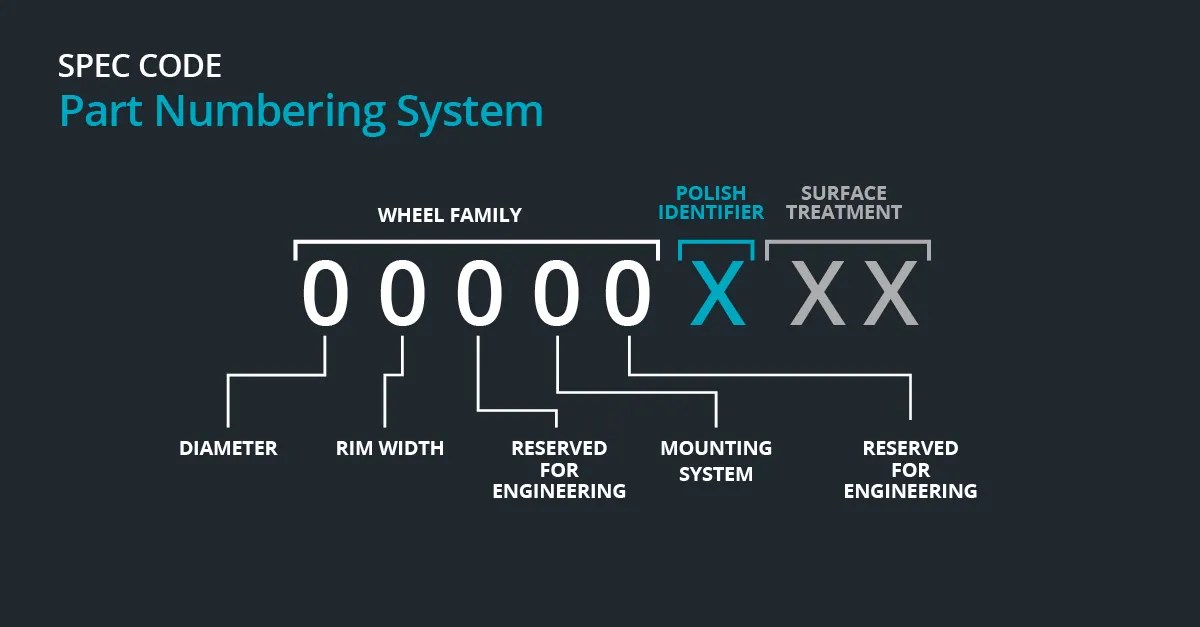

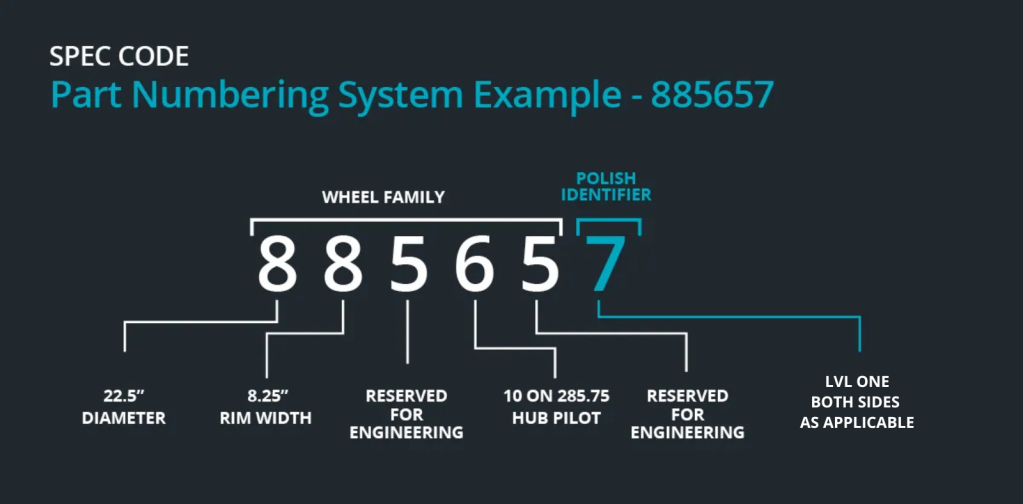

To spec your wheels, call 1800 955 191 to talk with our wheel experts, or fill out a contact form, and we will contact you to answer your questions and discuss your specifications.