Maximizing the life of a wheel’s original finish starts with regular washing and using mild detergents and soft bristled brushes, and there are also several other ways in which you can get the most out of your investment and avoid having to replace wheels prematurely.

An active fleet wheel maintenance program keeps your trucks traveling safely, extends the life of your tyres, and creates less downtime, so your fleet’s productivity stays up.

Your drivers will also appreciate the peace of mind that comes with a well-maintained vehicle. Get things right at the wheel ends and you will maximise the life of your wheels

1. Make sure tyres are not over or under-inflated

Check the tyre pressure regularly and adjust to the manufacturer’s recommendations – overinflated or underinflated tyres can cause problems with your truck’s handling, which can lead to premature wear on wheels and therefore unnecessary replacements.

Because over-inflated tyres are harder than properly inflated ones, they become more susceptible to punctures and impact breaks.

The over-inflation can affect tyre traction and lead to irregular wear patterns. Under-inflated tyres are also dangerous because they generate excess heat which can weaken the internal tyre structure – making your truck or trailer use more fuel.

2. Inspect wheel nuts and bolts for tightness and re-tighten as necessary

If you detect rust streaks, it usually means you have a loose fastener or broken stud. Look for missing valve caps, broken studs, rust streaks from bolt holes, cracks in the washers of hub-piloted wheels, variations in the number of stud threads, wheels/drums not seated properly on the hub, cracks or damage on any wheel component, excessive pitting or corrosion that has reduced material thickness and the recommended tire pressure.

In a recent article on maintenance advice for fleets, Dave Waters | Manager of Warranty and Field Service for Alcoa Wheels, stated:

“The studs are stretched every time wheels are torqued up. They act as a spring in the system, so making sure they are not stretched beyond their yield point is critical. Studs can be checked with a tread gauge.”

Dave Waters | Manager of Warranty and Field Service for Alcoa Wheels

He continued: “The nuts are critical, especially on a hub pilot wheel system, because they have at least two pieces of a nut body and a washer base.”

Walters also added that nuts require free movement between the body and the base, and he recommended “a drop or two of oil” for the nuts every time they are installed, as well as a drop or two of oil on the studs.

Loose wheel nuts cause stress on the stud hole, which in turn may cause a wheel off situation.

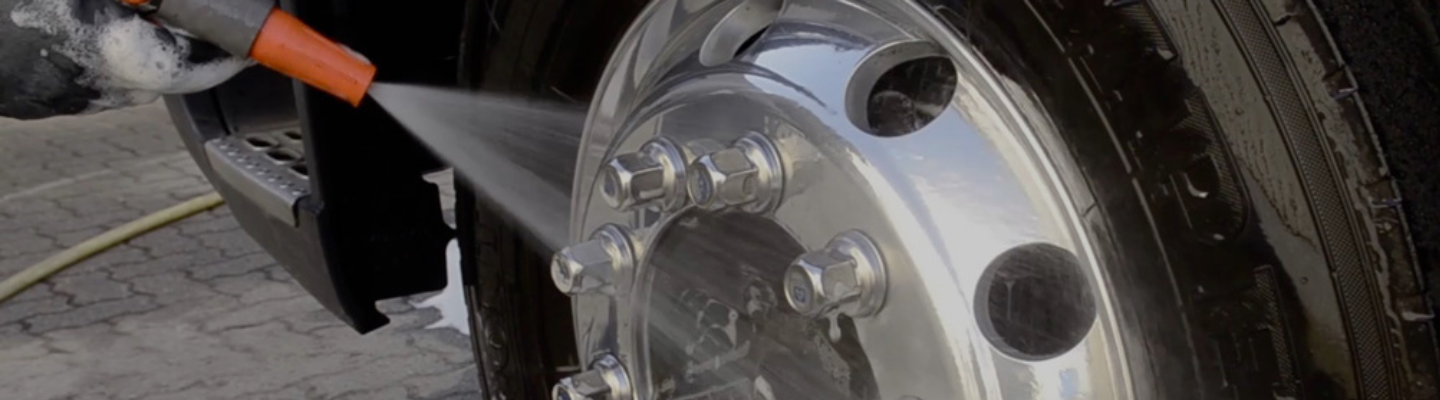

3. Clean Alcoa wheels with a non-abrasive cleaner and a soft cloth

The build-up of dirt and grime can lead to corrosion, which dulls and pits wheels. Using strong detergents, alkaline or acidic cleaners can etch the surface of the aluminium and cause the dull areas on the wheels, too.

4. Apply an aluminium polish every few months to keep your Alcoa wheels looking shiny.

how-to-clean-db-before-after. If you don’t want to have to polish your wheels, Alcoa Dura-Bright® surface treatment cleans with just soap and water and maintains the wheels’ shine without the need to polish.

5. Rotate your truck wheels on a regular cycle to improve their tyre life.

6. Balance your truck wheels periodically. Out of balance wheels and tyres can cause vibration and premature wear.

Always follow the manufacturer’s guidelines when taking care of your heavy-duty equipment.