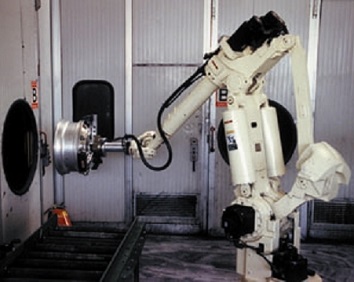

Alcoa® wheels are forged from one solid block of aluminium.

Every wheel starts as a single block of high-strength aluminium alloy.

With an 8,000 tons press, the block is forged into a wheel shape. Once forged, the wheels are heat-treated to maximize overall mechanical strengths.

Precision machining ensures that each wheel is perfectly round. This reduces runout to a minimum.

The ventilation and mounting holes are drilled.

The last step is the finishing into “Brushed”, “LvL ONE®” or “Dura-Bright® EVO”.

The Howmet forging process for Alcoa® Wheels aligns the grain flow of aluminium with the shape of the wheel. This process results in wheels with unrivalled forged strength that withstand the most severe tests.

We are so confident in the durability and quality of our wheels that we give a 5-year unlimited mileage warranty.

The best solution for your business

Alcoa® wheels are a must. The perfect choice for your vehicles.

Be the toughest on the road

More than 3 times stronger than steel wheels

Alcoa® Wheels performed more than 3 times stronger in a deformation test conducted by Széchenyi István University, Department of Vehicle Manufacturing and Technology, 2023 compared to the steel wheel of a market-leading brand with the same dimensions and load rate.*

Find all information about the testing here: https://www.alcoawheels.com/europe/en/strength-test

Be the lightest on the scale

By switching from steel to aluminium Alcoa® wheels you can easily save up to 51% in weight, depending on the wheel size, allowing you to:

- increase the vehicle’s payload

- reduce your operating costs

- boost your profitability

Calculate your individual weight saving with the Alcoa® wheels Calculighter

*Compared to exemplarily steel wheel weights with same dimensions and load rates.

Be greener and cleaner

Alcoa® wheels are:

*Source: ThinkStep (2017) Comparative Life Cycle Assessment of Aluminium Alcoa® wheels and Steel Wheels for City Buses

** Source: ThinkStep (2018) Comparative LCA Aluminium Alcoa® wheels vs. Steel Wheels for longhaul trucks

Save up to 1.29% fuel

Steel wheels* vs. Alcoa® aluminum wheels**

Summary

Fuel Savings: 0.29l/100km (1.29%)

Constant Speed test runs (CST) with a heavy-duty semi-trailer combination, based on Annex VIII of Commission Regulation (EU) 2017/2400 and additional fuel consumption test results.

Test Vehicle: Long-Haul truck/trailer combination with aerodynamic components

Truck Steer: 22.5″ x 9.00″ Alcoa® Ultra ONE® wheels

Truck Drive: 22.5″ x 9.00″ dual Al torque wheels Kistler RoaDyn P1HT

Trailer: 22.5″ x 11.75″ ET120 Alcoa® Ultra ONE® wheels

Alcoa® aluminium wheels were tested against two models of steel wheels used on the same test truck/trailer combination. Find steel wheel specifications in report section 4.2.1* and Alcoa® aluminium wheel specifications in report section 4.2.2**.

Calculate your estimated fuel saving opportunities with the Alcoa® Wheels Fuel Saving Calculator. Estimates are based on the conditions detailed in test report [Download the full test report here]. Individual fuel savings will vary depending on specifications of vehicle and other parameters.

This comparison may not reflect the most recent development and accuracy of the information herein is not guaranteed. Howmet Aerospace reserves the right to change information in this comparison, including the technical characteristics and designs of Alcoa® wheels.

Great looks and timeless design