Dura-Bright® EVO

Breakthrough Technology

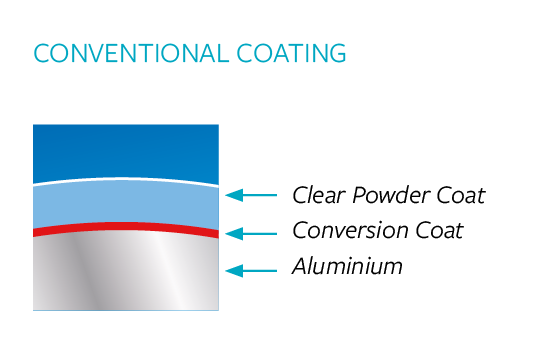

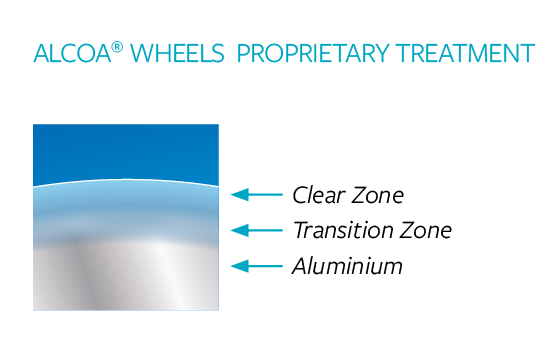

On most aluminium wheels, a coating is typically a layer of baked powder that sits on top of the wheel surface. When scratched, water and salt will penetrate the coating, resulting in corrosion and further deterioration. Dura-Bright® ALCOA® WHEELS have a proprietary treatment that penetrates the aluminium and becomes an integral part of the wheel. It will not chip, crack, peel or corrode, like conventional coatings do.

What happens on the road, stays on the road

There is no easier wheel to maintain than a Dura-Bright® wheel. Thanks to the patented surface treatment the wheels will look bright and shiny for years without polishing.

Dura-Bright® wheels can simply be cleaned with a mild detergent or undiluted Dura-Bright® Wheel Wash.

Black and Green

Dura-Bright® EVO wheels are easily recognizable by their black and green Alcoa® Dura-Bright® EVO sticker. Part numbers ending in DB are Dura-Bright® treated.

Dura-Flange®

Additional protection for an even longer service life

Dura-Flange® ALCOA® WHEELS have a proprietary treatment that provides a protective shield to reduce rim flange wear, giving them up to double the lifetime compared to other aluminium wheels under the same conditions.

Road tested

Dura-Flange® ALCOA® WHEELS show no signs of rim flange wear after 386.000 km .

Dura-Flange® wheels are the most appropriate for transport where loads are heavy and prone to shifting, causing the tyre bead to rub against the wheel flange, such as:

Rim Wear Protected

Dura-Flange® wheels are easily recognizable by the “Rim Wear Protected” sticker. Part numbers ending in DF are Dura-Flange® treated.

Dura-Bright®/Dura-Flange®

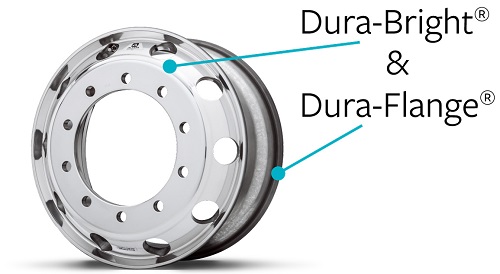

2 revolutionary treatments combined into one

Dura-Bright®/Dura-Flange® ALCOA® WHEELS are the result of 2 treatments combined, resulting in a shiny looking easy to maintain wheel with a protective shield to further increase the wheels’ service life.

Dura-Bright®

Dura-Bright® is not a coating, but a surface treatment that penetrates the aluminium and becomes an integral part of the wheel. It will not chip, crack, peel or corrode, like conventional coatings do. Regular cleaning with a mild detergent or undiluted Dura-Bright® Wheel Wash will keep the wheels shiny, even after hundreds of washes and thousands of kilometres, reducing maintenance costs.

Dura-Flange®

The Dura-Flange® treatment provides a protective shield to reduce rim flange wear, giving them up to double the lifetime compared to other aluminium wheels under the same conditions. Dura-Flange® is commonly used in transport where loads are heavy and prone to shifting, causing the tyre bead to rub against the wheel flange.

Black and Green / Rim Wear Protected

Dura-Bright®/Dura-Flange® wheels are easily recognizable by their black and green Alcoa® Dura-Bright® EVO and “Rim Wear Protected” stickers. Part numbers ending in DD are Dura-Bright®/Dura-Flange® treated.