Alcoa® Wheels didn’t stop at the invention of the forged aluminum wheel in 1948. We have continued to stay at the leading edge of innovation and are using our wheel technologies to help forge the future of the transportation industry. New technologies such as electric vehicles and fuel cell vehicles, along with decarbonization initiatives, fuel emissions regulations, green gas house emissions standards and sustainable city transportation are having an impact on how fleets operate. Vehicles are getting heavier due to the technologies required to meet climate change driven standards, and in the transport industry, every pound counts.

The Future of Electrification

We have seen a range of prototypes, demonstration trucks and commercially available hydrogen fuel-cell and plug-in electric vehicles come onto the market. Most recently, over 13 fleet and manufacturers participated in the Run On Less program and demonstrated the latest advances in electric truck technology. All-electric, zero-emissions trucking is becoming a reality.

Cummins Box Truck

Kalmar Ottawa Electric Terminal Tractor

What do Alcoa® Wheels have to do with electrification of vehicles?

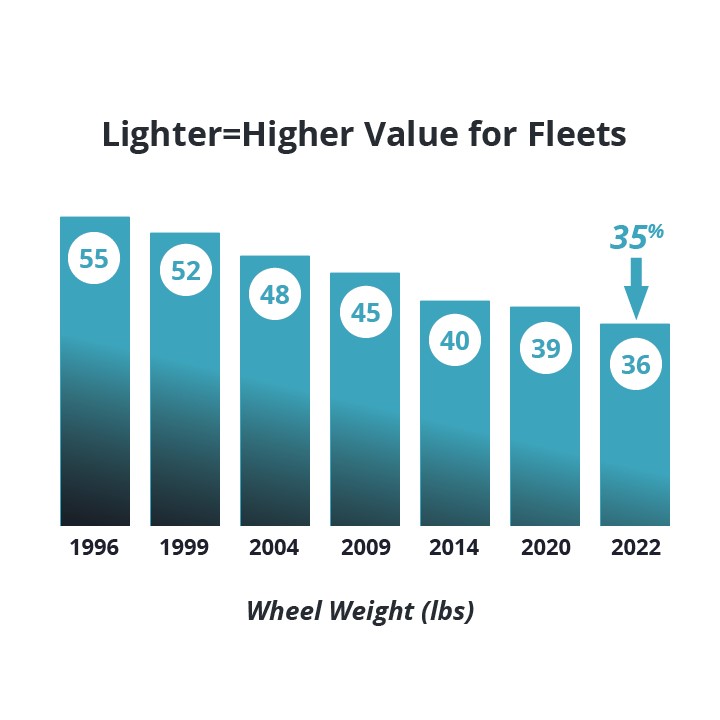

It’s about light weighting. Lighter wheels are becoming an increasingly important consideration as we move towards a more sustainable future. Fitting lighter wheels not only offsets the added weight of the battery, but they help extend battery life and improve range. As technology advances, Alcoa® Wheels continues to evolve its innovations. It’s a priority to strive to be the resource fleets can count on to bring the industry’s lightest and strongest aluminum wheel solutions to market. And now, things just got even lighter.

Alcoa® Wheels has launched the new 22.5” x 8.25” wheel, ULT36x, and the lighter Alcoa® 22.5” x 14” wheels, 84U61x and 84U64x. Upholding the world’s lightest truck wheel portfolio, which now boasts the world’s lightest wheel in commercial transportation, Alcoa®’s groundbreaking ULT36x 22.5” x 8.25” wheel is three pounds lighter than its predecessor, weighing just 36 pounds, and is equipped with proprietary MagnaForce® alloy.

Highlights include:

- Exceptional strength with a 7,400 lbs. load rating

- Alcoa® advanced finishes High Polish and Mirror Polish

- Exclusive Alcoa® Dura-Bright® and Dura-Black™ surface treatments

- Patent-pending wheel design

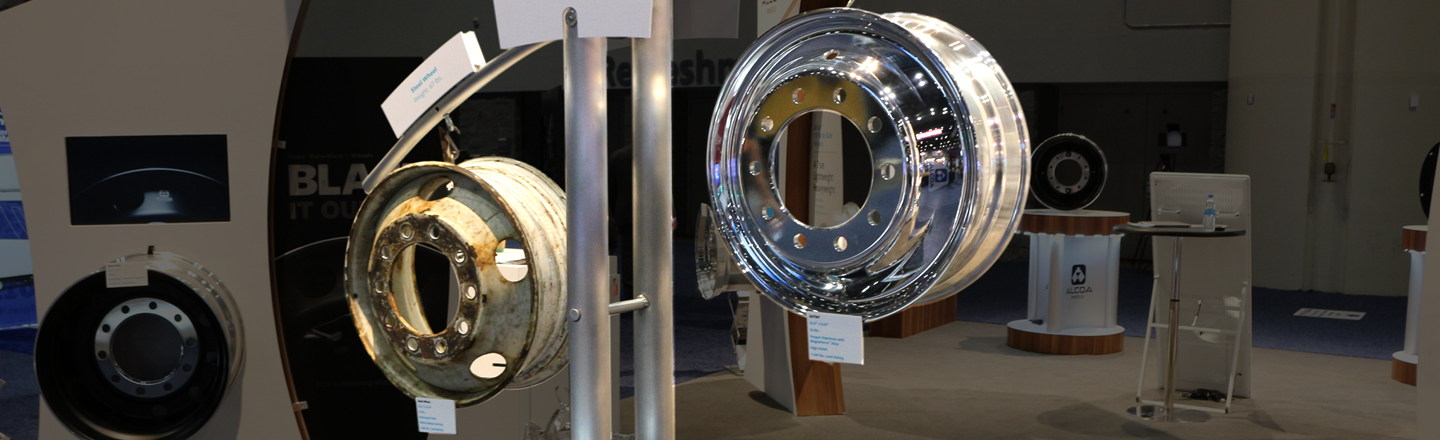

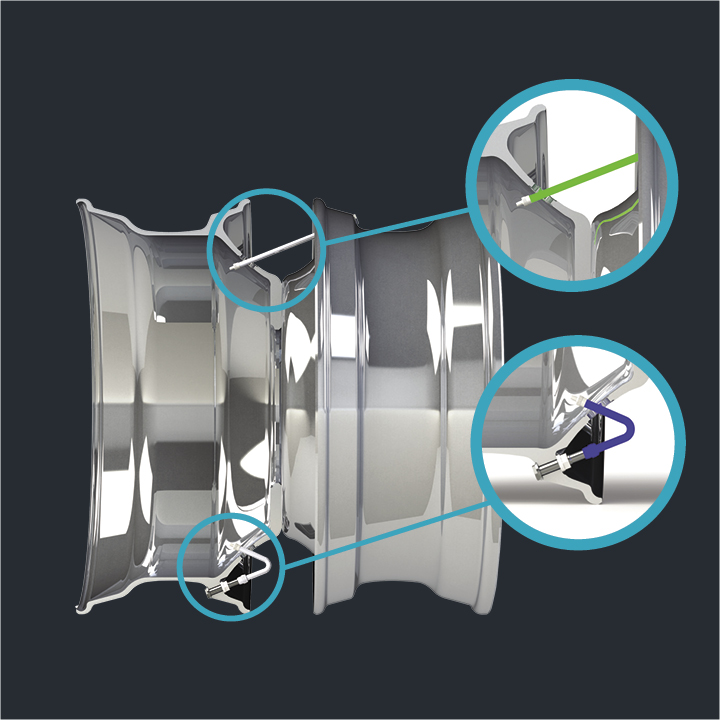

The new Alcoa® ULT36x wheel also features vHub™ Bore Technology, which reduces hub-to-wheel contact area by up to 64% versus other aluminum wheels on the market, leaving less surface area for corrosion to form. In addition, it is offered with a unique valve access designed for ease of inflation and pressure checks in all positions. The system works with ATIS and Halo Tire Inflator and brings both the inner and outer dual valve into the wheel well for improved access.

Along with the new ULT36x, Alcoa® Wheels now has the lightest 22.5” x 14” truck wheel on the market. At just 49 lbs., three pounds lighter than its predecessor and made with proprietary MagnaForce® alloy, the wheel provides a 12,800 lb. load rating. Weighing significantly less than a comparable steel wheel, fleets will save over 1,400 lbs. when converting from steel dual wheels and tires on an 18-wheeler.

It’s about reducing CO2 emissions. “A real-world study of 13 electric trucks delivering freight across North America has found that if all U.S. and Canadian medium- and heavy-duty trucks became electric, about 100 million metric tons of CO2 would be saved from going into the atmosphere.” https://nacfe.org/news/run-on-less-electric-demonstrates-co2-saved-with-electric-trucks/

A good example is shown in the bus segment where one OEM notes, “Weight needs to be reduced to get maximum battery capacity and passenger loading while respecting the various regulations (local, state, and federal).”

It’s also about a bit of everything. North American Council for Freight Efficiency’s (NACFE) Mike Roeth said it perfectly during a podcast on the Alcoa® Wheels Behind the Wheels. “The last thing I would say about this transformation is that it takes all of it. It’s not an either/or. It’s not just lightweighting or just low-rolling resistance tires and fine-tuning your powertrain for the duty cycle. Most all of those things will also help the range of these alternative fuel vehicles and save on the electricity that we need for battery electric trucks. So, efficiency is critical in being successful with these alternative fuel trucks.”

The Alcoa® Ultra ONE® 39 lb wheel is already helping fleets, owner-operators and original equipment manufacturers (OEMs) reduce individual truck and trailer weight by up to 504 lbs on a tandem tractor trailer when aluminum wheels are specified versus steel wheels, and up to 1,400 lbs when they specify wide base wheels and tires. The latest introduction of the 36 lb wheel is going to further impact fleets’ bottom line.

Alcoa Wheels’ innovative wheel technologies will continue to forge the future of the transport industry as it adjusts to demands to become more and more sustainable.