Switching one truck from steel wheels to forged aluminium wheels equals the carbon footprint of an average 4 person household.

The carbon footprint of the transport sector is one of the most common ways to measure the effect of the industry on the environment. An increase in greenhouse gas emissions, and therefore in carbon footprint, is believed to be the primary event associated with climate change that has led to global warming.

The trucking industry has been doing its part for the environment to lower emissions and improve the fuel efficiency of trucks on the road in recent years, and aluminium wheels are integral to the success of this undertaking.

Although the transport and agricultural sectors both contribute around a sixth of Australia’s net Green House Gas (GHG) emissions, worldwide the percentage of road transport CO2 emissions contributed by heavy duty vehicles is expected to reach 41% globally by 2030.

And despite Covid sending Australia’s carbon emissions plummeting in 2020 to the lowest levels in 30 years, it wasn’t long before they started to climb again with the easing back of lockdown restrictions.

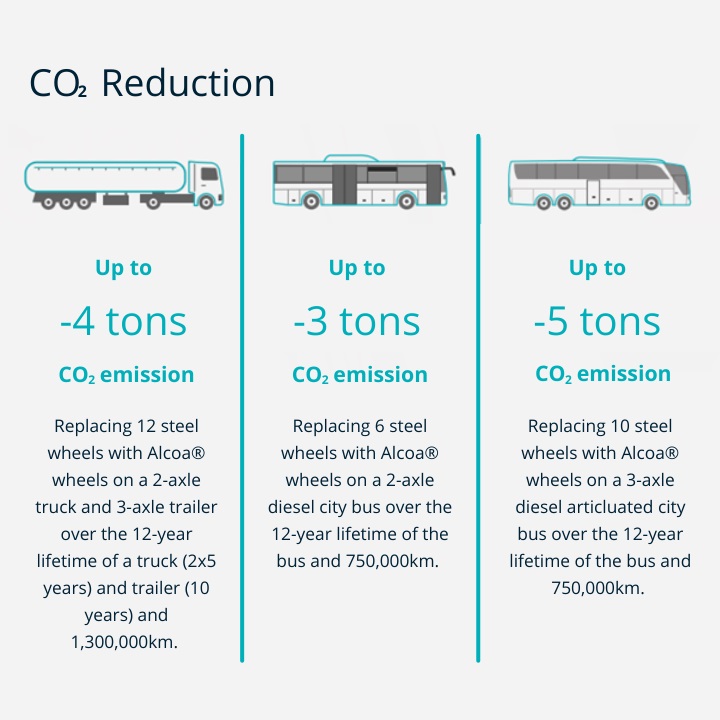

In 2012, Howmet Aerospace, manufacturer of Alcoa® Wheels, released the findings of a peer-reviewed life cycle assessment* (LCA) which concluded that Alcoa® forged aluminium wheels substantially cut the carbon footprint of commercial vehicles.

In North America, the study found that substituting 18 conventional steel truck wheels with Alcoa® aluminium wheels cut carbon emissions by 16.3 metric tons over the lifetime of the wheels.

In Europe, 13.3 metric tons of carbon emissions were cut by replacing 12 steel wheels with aluminium ones. It was concluded that the use of Alcoa® forged aluminium wheels over steel wheels could be viewed as an active and highly efficient investment into the reduction of greenhouse gas emissions in the commercial vehicle sector.

Here are 6 ways aluminium wheels are helping lead the sustainability effort in the transport sector and helping the planet:

1. LIGHTWEIGHT: AN ALCOA WHEEL IS UP TO 51% LIGHTER THAN A STEEL WHEEL

Today, in 2021, the pressure is on even more with stricter regulations around reducing carbon emissions, and with new technologies adding weight to commercial vehicles, there is a call for lighter, stronger wheels to offset these costs while at the same time keeping payloads lucrative and maximising fuel efficiency.

By switching from steel to aluminium Alcoa® Wheels, OEMs and fleets can easily save up to 51% in weight, depending on the wheel size, allowing them to:

- increase the vehicle’s payload

- reduce operating costs

- boost your profitability,all while doing their bit for the planet!

Adding over 200kg of additional payload per average haul with lighter wheels, plus reducing the fuel consumed per kg of cargo, increases the efficiency of the transport.

Given the lightweight properties of aluminium wheels, even the amount of energy required to transport the wheels to OEMs is significantly lower than steel, as illustrated here.

“Alcoa® Wheels support sustainable transportation by helping trucks and trailers to be greener,” says Ross Simmons, Managing Director of Howmet Wheel Systems Australia (distributor of Alcoa® Wheels). “Helping operators cut down on fuel use and carbon emissions is one of our biggest priorities, and we invest heavily in leading in the latest innovations to engineer lighter and lighter wheels”.

2. DURABILITY: HEAVY DUTY WITHOUT THE HEAVY

Aluminium wheels are tough enough to withstand both the rigors of the most challenging climatic conditions – from cold to wet to hot.

Alcoa® Wheels are forged from one solid block of aluminium. With an 8,000 tons press, the block is forged into a wheel shape. Once forged, the wheels are heat-treated to maximize overall mechanical strengths.

The Alcoa® Wheels forging process aligns the grain flow of aluminium with the shape of the wheel, even in the critical area where disc and rim meet. This process results in wheels with unrivalled forged strength that withstand the most severe tests to ensure highest standards and quality.

Howmet Wheel Systems, distributor of Alcoa® Wheels in Australia, are so confident in the durability and quality of Alcoa® wheels, they give a 5-year unlimited mileage warranty.

Fitting durable, long lasting wheels to your equipment, minimises the need to replace wheels and reduces your impact on the environment.

3. RESISTANCE FROM CORROSION: AN ALCOA DURA-BRIGHT® WHEEL IS 10 X MORE RESISTANT

What makes aluminium wheels so resistant to corrosion is that the metal spontaneously forms a thin but effective oxide layer that prevents further oxidation. Aluminium oxide is impermeable and, unlike the oxide layers on many other metals, it adheres strongly to the parent metal.

Alcoa® Wheels’ low maintenance surface treatment, Dura-Bright®, has been engineered to bond with the aluminium even more by penetrating the metal to form one composite 3 times more resistant to chemicals and 10 time more resistant to corrosion than ‘standalone’ aluminium.

Using less harsh chemicals to clean your wheels reduces your impact on the environment.

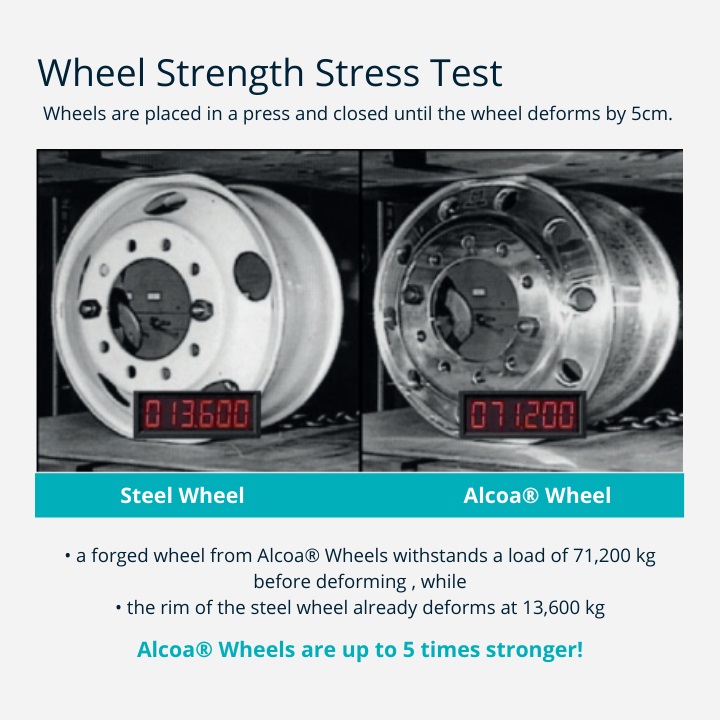

4. STRENGTH: THE STRONGEST WHEELS ON EARTH

Aluminium alloys are what makes aluminium one of the toughest metals on earth. Alcoa® Wheels are manufactured using a patented MagnaForce® Alloy which has strengthened the wheels by 17% over the industry standard 6061 alloy used for aluminium wheels worldwide.

The stronger the wheel, the more load it can bear. The Alcoa® Ultra ONE® Wheel, for example, weighs just 18kg and can carry the same load (3555kg) as its predecessor over ½ a kg heavier.

Increasing payload helps you reduce the number of trips it takes, therefore saving you in fuel and other consumables and thus saving the environment.

5. 100% RECYCLABLE

Aluminium can be recycled forever.

Recycling an Alcoa® Wheel at the end of its useful life will generate a piece of metal with exactly the same properties as the metal used to manufacture the recycled wheel. Once the new product reaches the end of its useful life, the same process can be performed again and again.

In the recycling process, almost all of the quantity of the material is preserved – and this process can be repeated almost infinitely.

Aluminium recycling also saves huge economic and environmental costs compared with the creation of virgin metal. Each ton of aluminium recycled saves one square meter of land use and 24 barrels of crude oil equivalent of energy.

It saves more than 15 tons of fresh or sea water use, eliminates more than 9 tons of CO2 equivalent of greenhouse gas emissions, and avoids 2.5 tons of solid waste and hundreds of kilograms of other air and water-borne emissions and effluents.

6. LONG LIFE: AN ALCOA® WHEEL LASTS FOR DECADES

Aluminium is especially durable in end-use and it lasts for decades. During its life as an Alcoa® Wheel, it has no energy or resource demands, nor does it release any particular environmental hazard.

In the case of commercial vehicles such as buses, medium and heavy trucks and truck trailers, the lifetime energy savings range from 150 to 1,048 MJ, or 1.0 – 7.2 gallons of crude oil equivalent, and lifetime greenhouse gas emission avoidance ranges from 10 to 76 kg CO2 equivalent. These findings have been largely supported by the results of other similar independent studies across the world.

The aluminium industry’s view of the sustainability of its material is that each piece of the metal ever made should be used, recycled, and reused for multiple generations and none should be landfilled or permanently destroyed.

The implications of this vision for the permanent existence of aluminium wheels are tremendous for our planet.

Make Sure It’s An Alcoa® Wheel

To spec your wheels, ring ![]() 1800 955 191 to talk with our wheel experts, or fill out a contact form and we will reach out to you to answer your questions and discuss your specifications.

1800 955 191 to talk with our wheel experts, or fill out a contact form and we will reach out to you to answer your questions and discuss your specifications.

*Life cycle assessment (LCA) is the universally accepted method to comprehensively assess the environmental impact of a product. The findings of the Alcoa® Wheels LCA were based on the full life cycle of the wheels—from the raw materials, through the production, distribution, use, disposal, and recycling of the wheels.