Service Manual for Alcoa Wheels

For trucks, trailers, and buses. This manual for professionals explains wheel service, including mounting and demounting of ball seat and hub pilot mount wheels. The manual uses graphics, theme headings and subject labels to guide the reader through blocks of information. This structure allows wheel service personnel to quickly find the specific facts they need and skim over what they don’t. Other important reference text in the manual includes our five-year limited warranty.

Wheel Fitment

There are four major areas to confirm fitment of Alcoa aluminium wheels with any particular hub/wheel combination:

- Wheel mounting surface.

- Clearance with other wheel end components.

- Pilot bore fitment (hub piloted mounting systems), and

- Stud standout (thread engagement).

NOTE:

Do not exceed maximum wheel load and/or the maximum tyre load rating. Fitment recommendations are for REFERENCE ONLY. Customer must compare OEM vehicle load rating to maximum wheel load rating. Refer to tyre manufacturer’s recommendation for proper tyre pressure. Do not exceed the maximum cold inflation tyre pressure marked on the wheel. Before mounting the tyre, perform a wheel fitment check to ensure proper clearance from any obstructions.

WHEEL FITMENT CHECK PROCEDURE

- Remove one front wheel.

- Clean the mounting surface of the hub with a wire brush and remove any retainer (spring) clips.

- Hold the wheel on the hub and check for a flush mount. The mounting surface of the wheel must fit flush to the hub mounting surface. The backside of the wheel must not rest against any obstructions, such as the brake caliper, suspension components, balance weights, rivets, etc.

- Confirm pilot bore length is sufficient for hub piloted dual rear wheels. (SEE PILOT BORE LENGTH)

- Install three lug nuts and hand tighten. Rotate the wheel and turn the steering column fully in both directions to ensure clearance from any obstructions.

- Confirm stud standout is sufficient. (SEE STUD STANDOUT)

- Repeat steps for rear wheel as they apply.

PILOT BORE LENGTH (Hub Piloted Wheels)

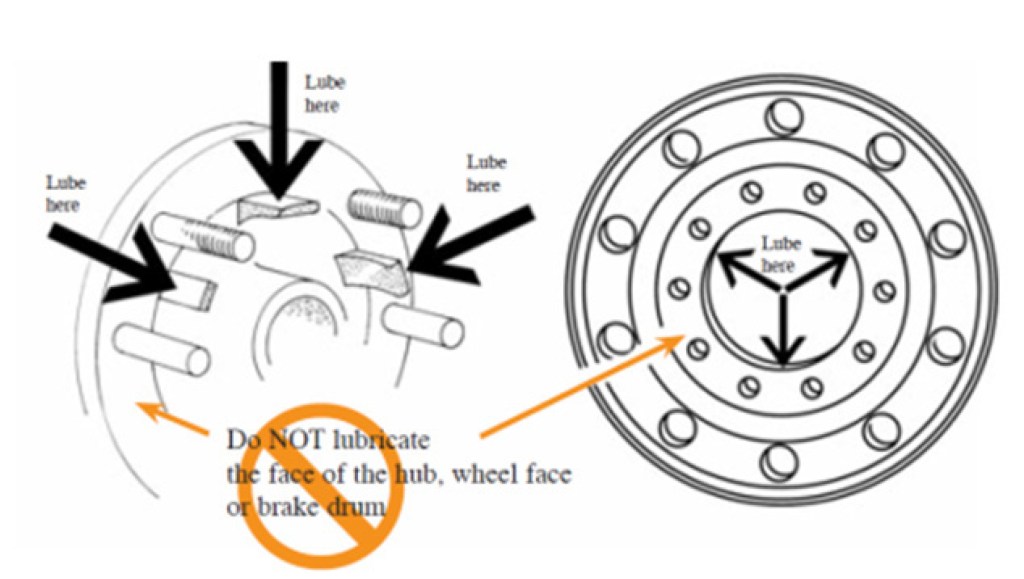

Specify only hubs that are designed for aluminum hub piloted wheels. Hubs designed for steel hub-piloted wheels may not have sufficient pilot length to locate dual aluminum wheels. (Measure the hub pilot to make sure the hub has a minimum pilot length that allows no less than 5mm for the outer wheel excluding the beveled edge.) Before final mounting of hub-piloted wheels, lightly coat the wheel pilot or hub pads with a non-water-based lubricant, such as Freylube or equivalent, to minimize corrosion build up. DO NOT LUBRICATE THE FACE OF THE WHEEL OR THE HUB.

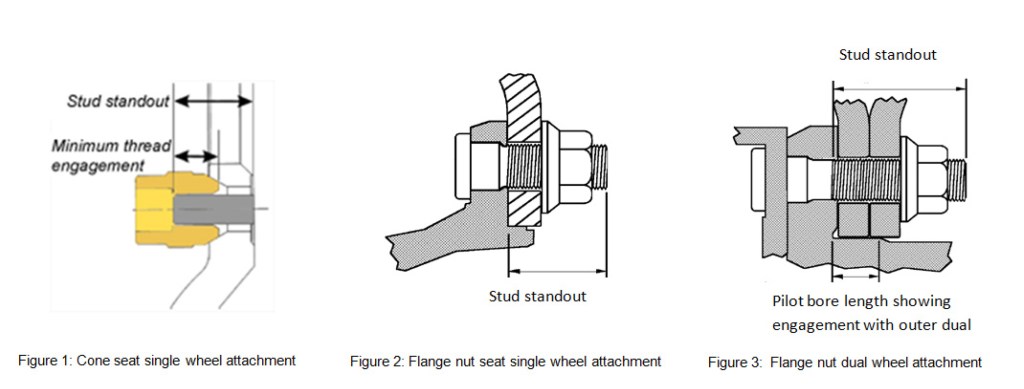

STUD STANDOUT

Stud standout is the length of the stud from the wheel-seating surface (hub or brake drum) that penetrates the wheel and engages the nut. This will dictate the amount of thread engagement obtained with any particular hub,/drum, wheel and nut combination. For 5-, 6- and 8-hole cone seat wheels (Figure 1) the minimum thread engagement (length of stud threads in the cap nut) is equal to the diameter of the stud (approximately 10 full turns of hand tightness). For ball seat and flange nut mounted wheels most states have laws which dictate full thread engagement or thread engagement past the nut body. (Figures 2 & 3) Ensure that you know the laws for the states you operate and comply. Depending on the standout, inner steel and an outer aluminum wheel may be required for specific applications. In some cases Alcoa provides alternate mounting hardware that can be used to replace the stock mounting hardware thus allowing the use of 2 aluminum wheels in the dual configuration. Please see the Alcoa wheel fitment guide or M-Series™ specification guide.

NOTE

Alcoa wheel axle covers for 16×6 and 16×6.5 dual wheels can only be used with Alcoa lug nuts (P/N 139987 and P/N 139698). These are not push-through axle covers. Do not use OEM cap nuts with Alcoa axle covers.

For Alcoa ball seat wheel applications refer M-Series™ specification guide for vehicle application and proper mounting hardware kits. Refer to your OEM for mounting instructions. Refer to Alcoa service manual for additional mounting instructions.

Arconic does not authorize, condone, or suggest the use of wheel adapter plates. Use only recommended hardware on Alcoa aluminum wheels.

WARNING: Use of a wheel adapter plate with dualed Alcoa wheel assemblies can cause insufficient thread engagment of lug nuts on studs. This condition can cause wheels to loosen and disengage from the vehicle, causing injury or death. Never use wheel adapter plates with Alcoa wheels.

WARNING: Use of cap nuts that have chrome plating on the contact surfaces can cause reduced and inconsistent wheel clamping. This condition can cause wheels to loosen and disengage from the vehicle, causing injury or death. Never use cap nuts with chrome-plated contact surfaces. Use only recommended hardware on Alcoa aluminum wheels.