Truck and trailer wheels made from aluminium do cost more money up-front, there’s no denying it. But as it turns out, they are the smarter investment in the long run – especially with the Australian government’s extension of the Instant Asset Write-off tax break.

With the Instant Asset Write-off, businesses can claim an immediate deduction of the cost of an asset in the year the asset is first used or installed ready for use. At the time of writing this, the assets will need to be used for the first time or installed ready for use by June 30, 2023.

“The extension of temporary full expensing to 2023 will continue to drive trucking business investment and help more businesses purchase safer trucks and trailers,” Australian Trucking Association CEO, Andrew McKellar, has said.

What this means for Australian transport business owners who may need to replace equipment, increase equipment numbers and/or improve equipment, is that now could be the time to explore Alcoa® Wheels when buying a new truck or trailer, or upgrading their wheels to Alcoa Dura-Bright® Wheels.

“Trucking businesses have rightly seen the measure as a once in a lifetime opportunity to renew their fleets,” McKellar said.

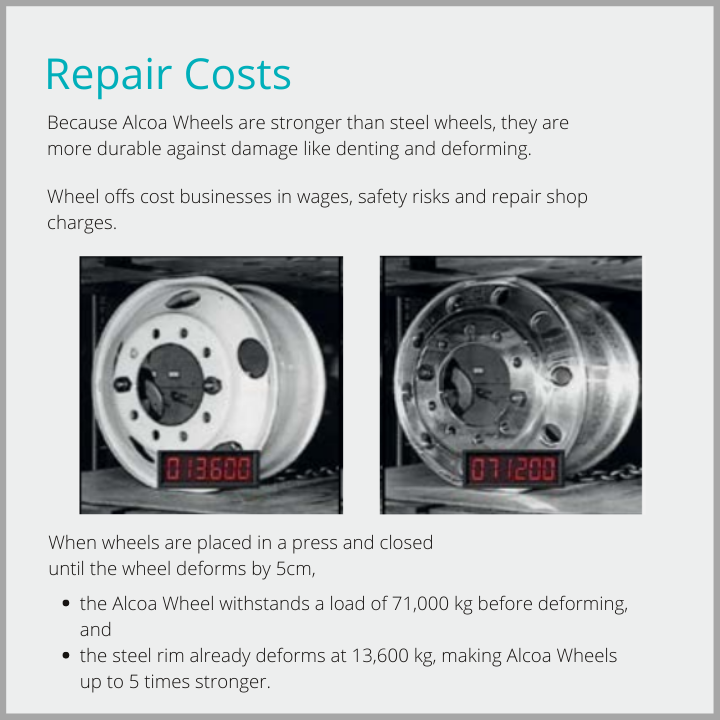

It’s no secret that forged aluminium truck wheels cost more money than steel wheels, so often this seems like the most economical choice.

A 22.5” by 8.25” steel wheel sells for between $100 and $140. An aluminium wheel, like the Alcoa Ultra ONE® wheel, in the same size can cost two to three times that.

While it might seem economical to go for a cheaper wheel, aluminium wheels work out to be a smart investment for a transport company’s bottom line in the long run.

Here are some of the key benefits of Alcoa® Wheels and 6 reasons why they make more financial sense than generally believed:

1. Fuel Savings

Many people know that investing in the right set of tyres can cut down on rolling resistance and therefore increase fuel savings.

When Alcoa wheels are combined with low rolling resistance tyres, the fuel efficiency is maximised again by some 3% or more! And this is supported by research – a 2012 study of Alcoa forged aluminium wheels in the US.

The study also found that the fuel efficiency savings of Alcoa wheels contributed to a decrease of the carbon footprint of commercial vehicles; so much so that trucks that switched from steel to aluminium reduced carbon emissions by 16.3 metric tons over the lifespan of the wheels, which equals the carbon footprint of an average 4 person household over a year’s time!

According to the North American Council for Freight Efficiency, light weighting technologies save 0.5% to 0.6% of fuel per 450-500kg (1,000 pounds) of weight reduction.

Upgrading to the new Alcoa Ultra ONE® 18kg wheel from the equivalent 22.5” x 8.25” steel wheel, for example, will lighten a standard truck and trailer by over 600kg.

If we calculated that over the 14 year lifetime of a truck and 10 year lifetime of the trailer, there are some substantial fuel savings to be had.

Some businesses, like bulk haulage companies, will want to replace the weight saved with more payload, so one could argue that the above equation isn’t valid, but read on and see what is possible for businesses where payload is a consideration.

If payload isn’t a factor in your business ie you don’t get paid by the load, more load means a decrease in the number of necessary hauls over time, which reduces the amount of fuel consumption as well.

2. Payload Gains

For bulk haulage fleets, the extra payload capacity drives wheel choices.

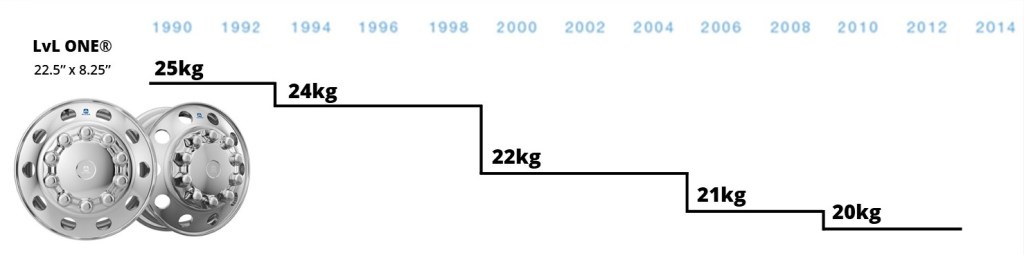

The newest Ultra ONE® Wheel, at just 18kg, can lighten a rig by over 100kg* against the average aluminium wheel of the same size, which can weigh 23kg.

Compared with a steel wheel of the same size, the weigh difference is upwards of 600kg.

Work out your savings with our payload calculator.

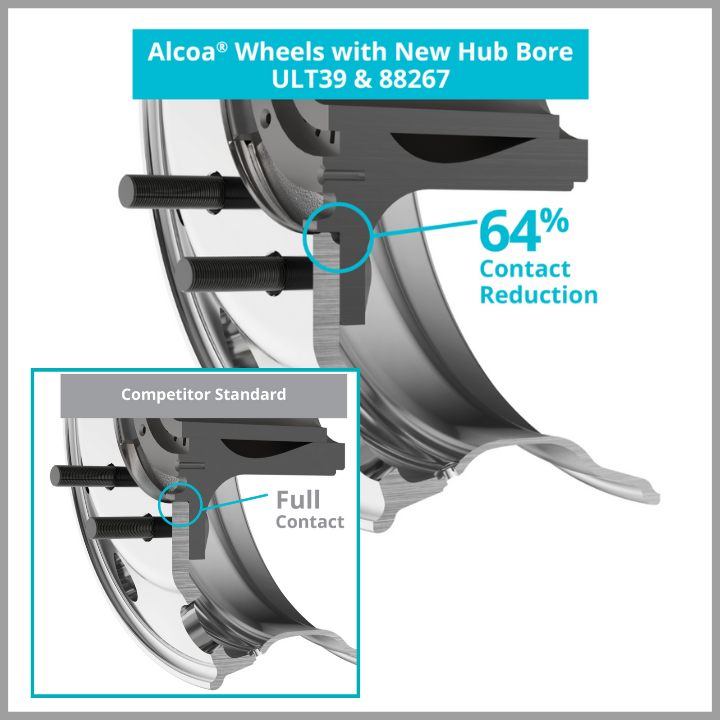

“Weight reduction is an ever-present goal for commercial wheel manufacturers,” says Ross Simmons, Managing Director of Howmet Wheel Systems – distributor for Alcoa Wheels in Australia. “We continue to find new opportunities for weight reduction without sacrificing performance and durability as we innovate with manufacturing processes and metal technology.”

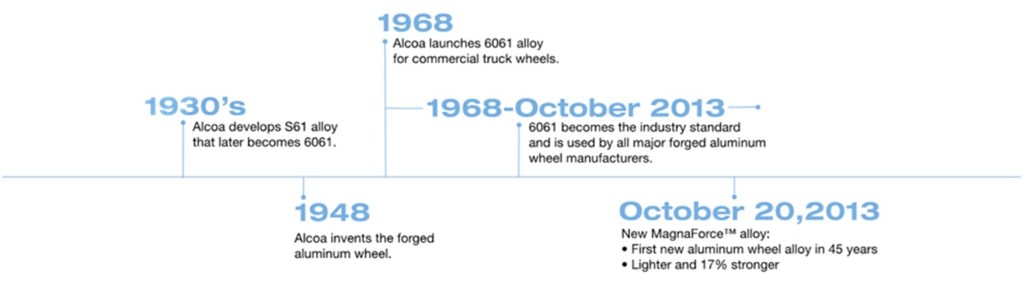

The patented MagnaForce® Alloy used for all new releases of Alcoa Wheels is 17% stronger than the industry standard alloy used to manufacture aluminium wheels, which has allowed Alcoa Wheels to reduce the weight of the wheel while still maintaining the load rate strength.

3. Low to No Maintenance

If we’re still talking ‘cheaper wheels’ being steel, it’s worth noting that although they cost less to purchase up front, steel wheels are high-maintenance ie labour intense – and labour = $$$.

Steel requires a lot of refurbishing such as removing rust, re-painting, and touch-up work, leading to higher lifetime costs.

Maintenance is one of the measurable costs that help transport business owners justify the financial sense aluminium wheels make because refurbishing, curbing damage, tyre and brake life are all part of the choice of wheels at the time of manufacture of the equipment, or replacement of wheels.

By their very nature, wheels in the heavy-duty world, spend their entire lives in harsh environments. They are constantly bombarded with potential corrosion and dirt build up.

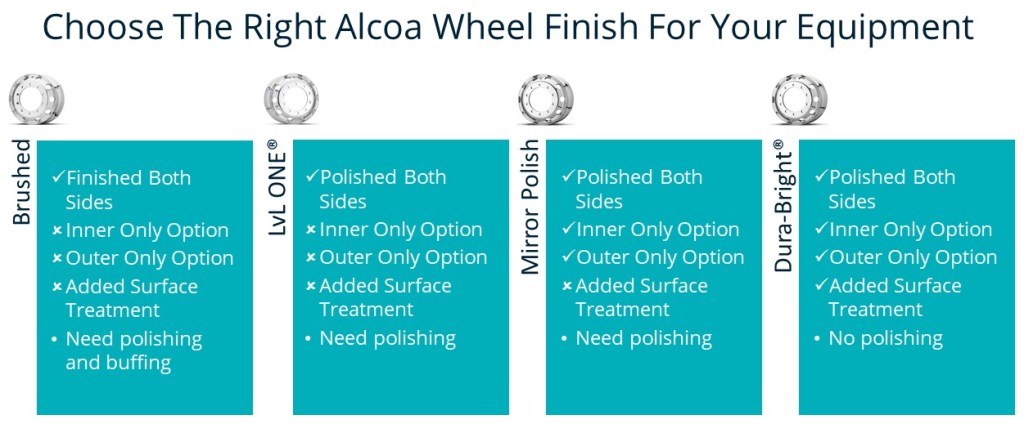

Alcoa Dura-Bright® Wheels, on the other hand, are cleaned with just soap and water.

Dura-Bright® Wheels are a premium surface treatment – not a coating – that actually penetrates the metal to form one composite.

This composite creates a lower surface energy, so less dirt and road grime sticks to the wheel.

It also enables the wheel to keep its shine, and so the wheel stays looking newer for longer without the need to polish, even after hundreds of washes and thousands of kilometres.

The ROI here is easily calculated: labour and time saved cleaning, less wheel offs due to Dura-Bright® wheels being 10 x more resistant to corrosion, and more time on the road hauling loads.

Dura-Bright® Wheels have been known to reduce wheel cleaning time from 25 minutes down to just 2 minutes.

Combining the advantages of lightweight Alcoa Wheels with the easy to clean benefits of the Dura-Bright® finish helps to lower lifetime operating costs and provide value to fleet owners.

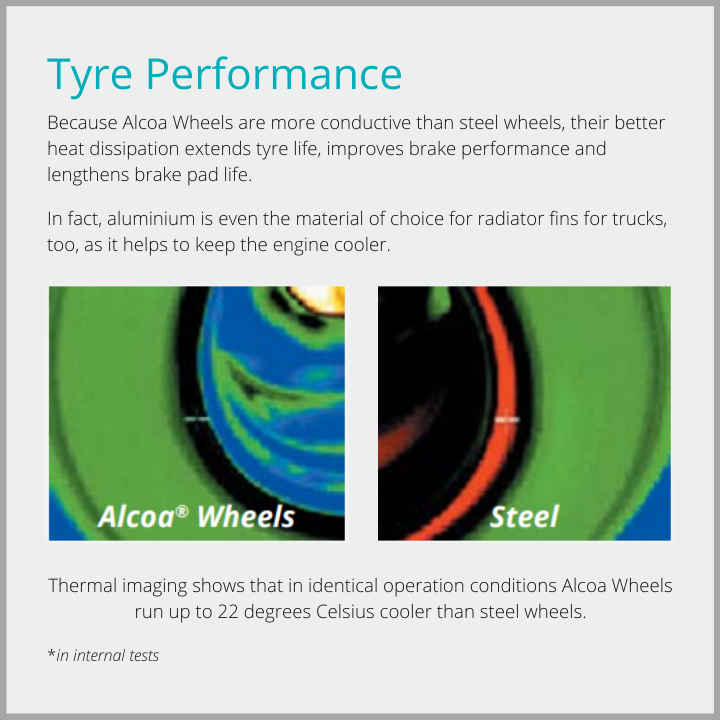

4. Extended Tyre and Brake Life

Improved heat dissipation can lead to longer tyre and brake life, so whether trucks and equipment are exposed to high temperatures due to harsh weather conditions, or they are start and stopping in high density city areas, the advantage of aluminium wheels is that they give up heat faster and dissipate heat away from the tyres and brakes – thus helping to improve tyre and brake life.

If the truck and trailer were on steel wheels, the heat would continue to rise even after parking the trucks. Alcoa Wheels help to quickly cool down the system and help to prevent heat damage to the tyres and brakes.

Because Alcoa Wheels are made from a one-piece aluminium machined on a CNC lathe, they are better balanced, which makes for improved ride quality and improve tyre life.

The cost of replacing tyres due to overheating can be lessened or even avoided, with that money staying in the business instead of being put into ongoing maintenance costs.

5. Driver / Operator Retention

Because Alcoa Wheels are 100 percent CNC machined, run-out and vibrations are eliminated leading to a smoother, safer ride for the operator.

This can potentially be measured as ROI in longer driver retention.

Employee satisfaction is directly proportional to how long a person remains in a role, and it has been recorded in a 2016 survey of 6200 truck drivers at two large fleets that those who believed their safety was prioritised by their employer felt more valued and were more likely to stay in their jobs.

6. Resale and End-of-Life

The durability and long life of Alcoa Wheels add value to commercial trucks and trailers, even when it is time to sell them. Research shows that trucks equipped with aluminium wheels have a higher trade-in value.

Wheel manufacturers report that the resale value of aluminium wheels is typically more than 50% of the original investment as much as 10 years earlier.

Even at the end of their very long life, Alcoa Wheels have value because they are recyclable. They will never be taken to a landfill.

Upfront Costs Remain Upfront

Price remains an issue for many businesses, which is why the Instant Asset Write-Off has been a godsend to many owner-operators, fleet owners and OEMs who have wanted to upgrade to aluminium wheels.

“We find that working out an ROI based on productivity gains helps in the decision to spec Alcoa Wheels,” says Michael Nichols, National Sales Manager for Howmet Wheels Systems Australia. “For example, we can quantify things like the reduction in maintenance costs, increased resale value due to the longevity of our wheels, and even driver retention.”

He adds: “The aluminium wheel choice is a long game, so to be able to take advantage of the government’s extension of the Instant Asset Write-Off now is making a lot of sense to business owners out there who can get behind the financial sense Alcoa Wheels makes over the lifetime of their equipment.”

The Preferred Choice of Leaders in the Industry

In the mining and heavy haulage sectors in particular, where every piece of the vehicle uses as much aluminium as possible because the payback is so great, Alcoa® Wheels are the preferred choice for leading OEMs in Australia.

How Does The Instant Asset Write-Off Work If I Want To Buy A New Trailer?

In a nutshell, if you buy your new trailer between now and 30th June essentially you will get an immediate tax deduction.

- Threshold amount is $150,000 (up from $30,000)

- Eligibility has been expanded to businesses with an aggregated turnover of less than $500 million (up from $50 million).

Businesses can claim an immediate deduction (business portion only) for multiple assets, new or second-hand, provided each asset costs less than $150,000.

Our best suggestion is to get onto your tax accountant STAT so that he or she can give you professional advice on what your options are.

You can also visit the ATO website to read up on what you can and cannot do.

Make Sure It’s An Alcoa® Wheel

Did you know that you can specify Alcoa® Wheels when buying a truck or trailer?

Ask for Alcoa® Wheels to be included in the quote. To spec your wheels, ring  1800 955 191 to talk with our wheel experts, or fill out a contact form and we will reach out to you to answer your questions and discuss your specifications.

1800 955 191 to talk with our wheel experts, or fill out a contact form and we will reach out to you to answer your questions and discuss your specifications.

*A standard truck and trailer with 22 wheels.

![]() 1800 955 191 to talk with our wheel experts, or fill out a contact form and we will reach out to you to answer your questions and discuss your specifications

1800 955 191 to talk with our wheel experts, or fill out a contact form and we will reach out to you to answer your questions and discuss your specifications